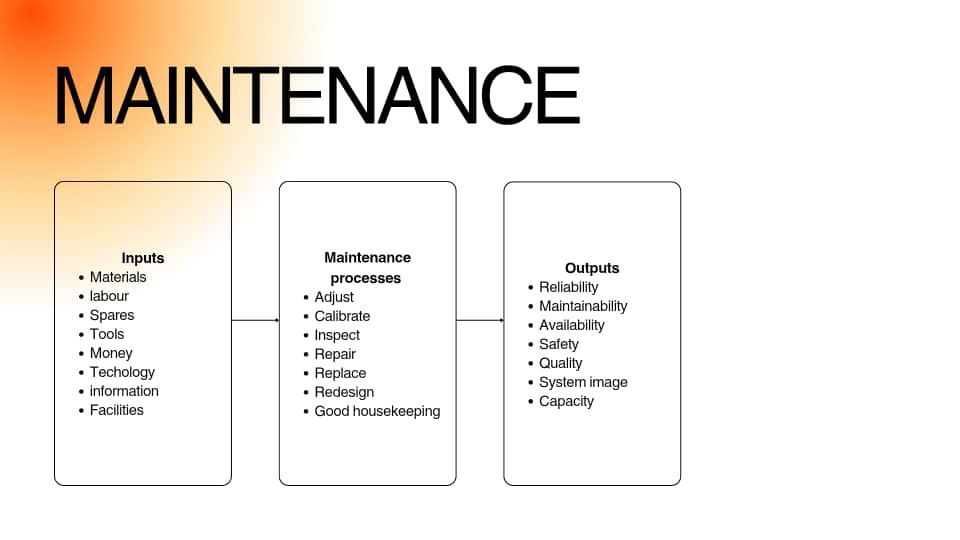

Maintenance is one of the most critical functions in Engineering. The main objective of maintenance is to maximise the availability of a physical asset. This also helps maintain an acceptable quality of products or service provided by the asset.

Maintenance therefore ensures that equipment, systems and infrastructure continue to operate safely, efficiently and reliably throughout their life cycle. Good maintenance prevents problems, reduces downtime and saves organizations from costly failures and breakdowns. Activities done during maintenance include inspection ( example is inspection of cables), repairs, replacement, cleaning, calibration, monitoring performance and upgrading outdated components. Simply cleaning the dust off solar panels the right way is maintenance.

Types of maintenance

There are basically two types of maintenance, this is corrective maintenance and Preventive maintenance. These can be further divided into other categories.

Corrective maintenance is commonly performed after a breakdown. Sometimes it is referred to as emergency maintenance. It also performed during shutdown, especially if an existing problem on the equipment is known.

Preventive maintenance is done mostly according to a maintenance schedule. It is performed before a failure or breakdown occurs. Preventive maintenance can be time-based, that is done at regular time periods. An example is car maintenance done after 100 000km of travel or an electric motor inspected every two months in a factory.

Maintenance Strategies

There are many strategies one can use for maintenance. Some can be tailored for your machines, business and finances.

There are three well known documented strategies that are used in manufacturing and service companies. These are Business-Centered Maintenance (BCM), Reliability-Centered Maintenance (RCM) and Total Productive Maintenance (TPM). These provide the template for most maintenance strategies.

The Future of Maintenance

With digital developments and technology advances such as A.I, Smart grids, IoT and Renewable systems,electrical systems are becoming more digitalised and connected. There is now better monitoring of systems, this means faults and breakdowns can be better predicated.

Therefore technology also has an impact on how maintenance can be done and structured. There is more focus on preventive maintenance. Investment on upgrades in these technologies have to be done for business to get the benefits. Personnel also have to be trained to make use of these technological developments.

Ultimately these take maintenance to a higher level of achieving its objectives, reducing breakdowns or failures and output at maxium. Thus keeping reliability and availability at its optimal.